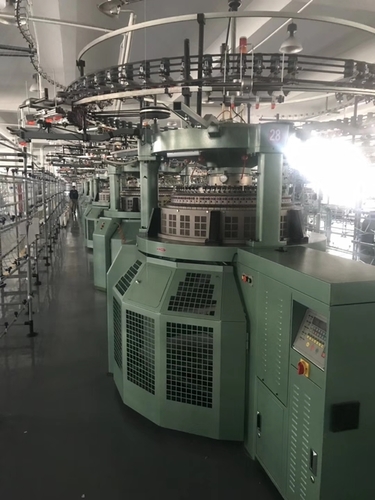

Jingmei Double Jersey Knitting Machine

Price 100000 INR/ Piece

Jingmei Double Jersey Knitting Machine Specification

- Power

- 3.7 kW

- Control System

- Digital Microcomputer Control

- Knitted Type

- Double Jersey

- System Support

- 2/3 Systems

- Drive Type

- Electric

- Dimension (L*W*H)

- 2450 x 2450 x 2300 mm

- Needle

- Cylinder and dial needle

- Application

- Apparel, Home Textile, Industrial Fabric

- Function

- High-speed double jersey knitting for various fabrics

- Color

- Sliver

- Knitting Method

- Circular Knitting

- Weight

- Approx. 2800 kg

- Product Type

- Double Jersey Knitting Machine

- Lead Time

- 30 Days

- Speed

- Up to 30 RPM

- Condition

- New

- Gauge

- 18G - 28G

- Stitch Density

- Adjustable via control system

- Racking

- 3 Track Racking

- Lubrication System

- Automatic Lubrication

- Operating Voltage

- 380V/220V (customizable)

- Material Capability

- Cotton, Polyester, Blends, Viscose

- Needle Type

- High quality steel needle

- Yarn Feeding

- Automatic Yarn Feeding System

- Fiber Compatibility

- Synthetic and natural fibers

- Feeder Quantity

- 36 - 72 feeders (varies by model)

- Frame Material

- Cast Iron & Aluminum Alloy

- Fabric Take-up System

- Central Fabric Roll-up Device

- Safety Features

- Emergency Stop, Overload Protection

- Noise Level

- Low, less than 80 dB

- User Interface

- LCD Touchscreen Panel

Jingmei Double Jersey Knitting Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 4 Pieces Per Day

- Delivery Time

- 2 Week

About Jingmei Double Jersey Knitting Machine

Advanced Knitting Performance

With its dual-needle configuration (cylinder and dial), the Jingmei Double Jersey Knitting Machine delivers superior fabric quality at speeds up to 30 RPM. The system accommodates a wide gauge range (18G28G) and supports double jersey fabrics, making it versatile for a variety of textile needs.

Precision and Automation

Benefit from automatic yarn feeding and lubrication systems, which minimize manual intervention and reduce maintenance downtime. Control over stitch density and feeder quantity ensures precise fabric characteristics, all managed via a user-friendly LCD touchscreen interface.

Built for Durability and Safety

A solid cast iron and aluminum alloy frame provides long-lasting stability. Key safety features such as emergency stop and overload protection, combined with a central fabric roll-up device, make operation safe and efficient, even under high-speed conditions.

FAQs of Jingmei Double Jersey Knitting Machine:

Q: How does the automatic yarn feeding system improve productivity?

A: The automatic yarn feeding system ensures consistent yarn supply to the needles, reducing the risk of tangling and downtime, and thereby enhancing overall knitting efficiency and output.Q: What types of fibers and materials can be processed on this machine?

A: This machine is compatible with both synthetic (such as polyester) and natural (such as cotton and viscose) fibers, as well as their blends, enabling versatile fabric production for various applications.Q: When should the lubrication system be maintained?

A: The integrated automatic lubrication system significantly reduces maintenance frequency. However, regular inspection as per the machines maintenance schedule is recommended to ensure optimal performance and longevity.Q: Where is this machine typically used?

A: The Jingmei Double Jersey Knitting Machine is widely used in apparel factories, home textile production units, and industrial textile manufacturing due to its adaptability to different fabric types and high-speed performance.Q: What is the process for adjusting stitch density?

A: Stitch density can be adjusted easily via the digital microcomputer control system and LCD touchscreen panel, enabling users to customize fabric tightness based on specific requirements.Q: How do the safety features contribute to secure operation?

A: Features like emergency stop and overload protection are designed to immediately halt operation in hazardous conditions, thereby preventing accidents and ensuring operator safety.Q: What benefits does the cast iron and aluminum alloy frame provide?

A: The robust construction of the frame ensures machine durability, stability during high-speed operation, and reduces vibration and noise, contributing to consistent high-quality fabric output.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Knitting Machine Category

Used Knitting Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Electric

Product Type : Used Knitting Machine

Condition : New

Application : Textile & Garment Industry

Runshan Double Jersey Jacquard Circular Knitting Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Electric

Product Type : Double Jersey Jacquard Circular Knitting Machine

Condition : New

Application : Caps And Scarfs

Mayer and Circular Knitting Machines

Price 100000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Electric

Product Type : Circular Knitting Machines

Condition : New

Application : Textile Manufacturing, Fabric Production, Knitted Garments

Double Jersey Knitting Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Electric

Product Type : Double Jersey Knitting Machine

Condition : New

Application : Caps And Scarfs

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS