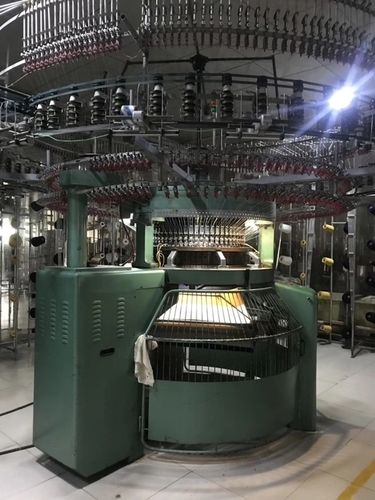

Mayer and Circular Knitting Machines

Price 100000.00 INR/ Piece

Mayer and Circular Knitting Machines Specification

- Racking

- Optional

- System Support

- Single Jersey, Double Jersey, Rib, Interlock, Jacquard

- Application

- Textile Manufacturing, Fabric Production, Knitted Garments

- Color

- Industrial Grey / Blue

- Drive Type

- Electric

- Stitch Density

- Adjustable

- Function

- High-Speed Fabric Knitting

- Needle

- Cylinder & Dial Needles / Groz-Beckert or equivalent

- Control System

- Automatic

- Warranty

- 12 Years Manufacturer Warranty

- Knitted Type

- Single Jersey, Double Jersey, Rib, Fleece, Terry

- Knitting Method

- Circular Knitting

- Product Type

- Circular Knitting Machines

- Condition

- New

Mayer and Circular Knitting Machines Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 4 Pieces Per Day

- Delivery Time

- 2 Week

- Main Domestic Market

- All India

About Mayer and Circular Knitting Machines

FAQs ofMayer and Circular Knitting Machines:

Q: What are circular knitting machines?

Q: What are the advantages of using circular knitting machines?

Q: What types of fabrics can be produced with circular knitting machines?

Q: Are circular knitting machines suitable for small-scale operations?

Q: How do circular knitting machines work?

Advanced Knitting Flexibility

These knitting machines accommodate diverse fabric types, including single jersey, double jersey, rib, fleece, terry, and jacquard. With versatile control systems and stitch density adjustments, users can seamlessly tailor the knitting process to specific fabric quality and production volume requirements, making them suitable for a wide range of garment and textile products.

Efficient Control and Operation

Featuring an automatic control system and electric drive, the machines are engineered for continuous, high-speed knitting. Optional racking expands design capabilities, while user-friendly interfaces enable easy monitoring and configuration adjustments, ensuring consistent quality and minimal downtime during large-scale manufacturing.

FAQs of Mayer and Circular Knitting Machines:

Q: How does the automatic control system enhance fabric production efficiency in these knitting machines?

A: The automatic control system streamlines operation by precisely managing stitch density and pattern settings, reducing manual intervention. This results in faster setup, consistent fabric quality, and optimal use of materials during production.Q: What types of fabrics can be produced with these Mayer and Circular Knitting Machines?

A: These machines are capable of producing single jersey, double jersey, rib, fleece, terry, interlock, and jacquard fabrics, making them suitable for a wide array of knitted garments and textile applications.Q: When should optional racking functionality be considered for textile manufacturing?

A: Optional racking is recommended when enhanced pattern versatility or more complex fabric structures are required. It allows for the creation of intricate designs and three-dimensional effects, supporting specialized textile products.Q: Where are these machines best utilized within the textile manufacturing industry?

A: These Mayer and Circular Knitting Machines are ideal for use in factories and production plants specializing in fabric and garment manufacturing, providing scalable solutions for both small and large-scale textile operations across India.Q: What is the process for maintaining these knitting machines, and how does the manufacturer warranty support users?

A: Routine maintenance involves cleaning, lubrication, and needle inspection or replacement using Groz-Beckert or equivalent parts. The provided manufacturer warranty (12 years) covers repairs and technical support, ensuring reliable performance and minimizing disruptions.Q: What benefits do the adjustable stitch density and versatile control system offer during operation?

A: Adjustable stitch density and a versatile control system enable precise customization of fabric texture and thickness, allowing manufacturers to meet diverse market demands while minimizing waste.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Knitting Machine Category

Jingmei Double Jersey Knitting Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Product Type : Double Jersey Knitting Machine

Drive Type : Electric

Control System : Digital Microcomputer Control

Jacquard Circular Knitting Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Product Type : Jacquard Circular Knitting Machine

Drive Type : Electric

Knitting Circular Machine

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Product Type : Knitting Circular Machine

Drive Type : Electric

Control System : Automatic

Tien Yang Auto Stripper Circular Knitting Machine

Price 100000.00 INR / Piece

Minimum Order Quantity : 1 Set

Condition : New

Product Type : Auto Stripper Circular Knitting Machine

Drive Type : Electric

Control System : Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS